Demand For Cold Storage Is Soaring and This Is Why

Covid-19 has changed the way many people shop for food, and at the same time, it’s thawing the frost that had settled over cold storage warehouses.

Growing demand for perishable food items and expansion of cold chain infrastructure are key factors driving warehouse industry growth. Besides, we have several more factors supporting cold storage market revenue growth, such as:

- Technological advancements and innovations in food cold storage facilities

- New packaging materials and techniques,

- The development of more efficient technologies for the processing and storage of food products

Large refrigerated warehouses built to preserve perishable goods at specific temperatures are becoming more advanced and demanded to meet the rise in online shopping and consumers’ expectations since users require the goods to arrive quickly at their doorsteps.

1. Rising Demand For Convenience Foods

Convenience food such as canned beans, tuna, and salmon, different sauces, cooked meals, washed greens, etc., is on its historic rise, and the preference for frozen bakery and confectionery products has also increased, driving market growth and awakening the need for more efficient storage facilities in the cold chain.

Maintaining the quality of frozen bakery and confectionery products (as well as other prepared and packaged food products) is highly dependent on the packaging, storage, and cooling.

Incorporating and processing temperature-sensible goods with cold chain solutions has become a major part of supply chain management.

2. Extending Packed Product Shelf Life, Maintain Quality And Hygiene

Cooling systems are primarily used for several very important reasons in stores:

- Firstly, they extend the shelf life of an edible product,

- They are used for maintenance of quality,

- They regulate the hygiene of packaged products, and sometimes

- Cooling systems improve product consistency.

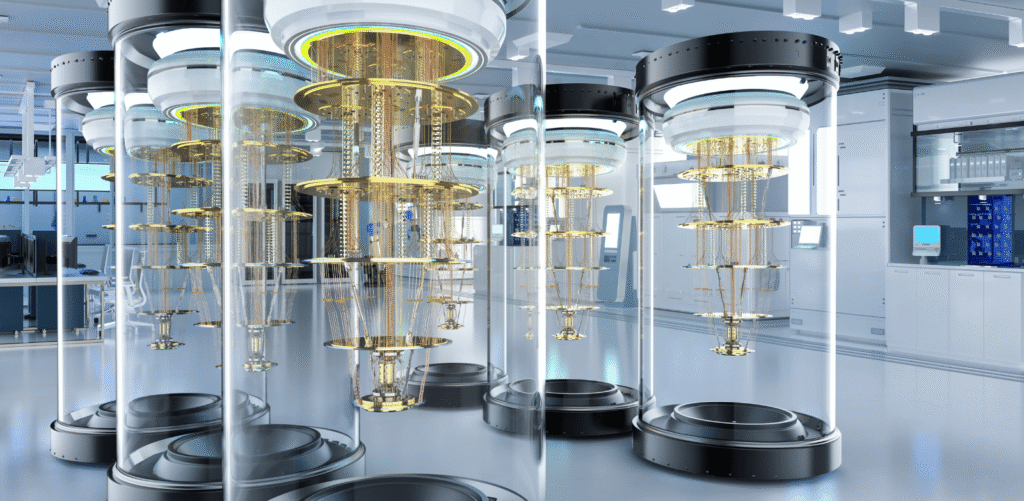

3. Technology Advancements And Lower Energy Consumption

Temperature-controlled warehouses are extremely energy sensitive due to high energy consumption, cooling, and ventilation systems.

However, recent technological advancements in the cold storage industry have been resulting in reduced energy consumption. Optimizing this energy usage and monitoring refrigeration equipment in cold storage facilities is imperative for reducing expenses and improving food safety while increasing operational efficiency.

A smart freezer warehouse automation and control systems are vital components in making buildings self-sustainable afterward.

Technologies in the cold storage chain have been advancing rapidly, driven by the growing need to ensure integrity, efficiency, and safety of shipments.

Today, a well-run cold-storage facility uses less than 30% of overall electricity power, greatly decreasing running costs and consequently reducing the impact on the environment. An increasing number of cold storage companies are rapidly shifting towards renewable energy resources such as wind and solar power to reduce overall operating costs.

4. Shifting To Online Shopping Preferences

With more people staying home, ordering take-out and online is popular more than ever. Online food sales went up nearly 85% in the past year, leading not just to a need for more cold room space but to facilities that are closer to population city centers.

The increasing shift in preference to shopping online for groceries, meals and other perishable products has been resulting in the rising need for retailers to expand their cold storage facilities.

Larger cold stores and cold storage facilities options facilitate better delivery and supply to end-users. Restaurants and catering companies are also increasingly adopting cold warehouse storage facilities due to the rising food demand.

5. Packaging And Transporting Materials

Materials play a major role in storing and transporting perishables, food, beverages, chemicals, and healthcare products, especially those that need to be in refrigerated trailers, insulated containers, or connected to refrigerated trucks, etc.

The increasing demand for refrigerated goods has also had an effect on the companies that transport those products worldwide. Temperature-controlled transportation businesses are being encouraged to innovate in order to keep pace with the ever-changing needs of the chilled market.

Recognizing the importance of guaranteed freshness, IPG offers fully integrated project management in wide-ranging real estate services, including warehouse and cold chain distribution systems.

COVID-10 made sustainability in today’s resource-stretched world no longer a luxury, but a necessity. Ensure professional handling of perishable items in safe warehouses – contact us. Learn more about the offer, overview, and pricing of WELL Certification you can obtain with our experts.